Quality Controls, QC

We Minimize Product Errors

Anyone who has dealt with China knows that cheating in both production and the packing of containers is common.

DisposablesInc.com make sure to minimize all kinds of fraud.

We minimize risk by making more quality checks along the entire production chain, from factory floor to shipping dock - depending on your requirements and specifications. You will be notified in the form of detailed reports and photographs within 24 hours after inspection.

Quality control before production

Quality control takes place just before production. We ensure that customer specifications and requirements are in agreement with the supplier and that the factory has all the information they need to go ahead with production. It is important for early identification of misunderstandings and errors. It saves time and money.

DisposablesInc.com check:

- Customer copies and specifications are in place

- The production process is properly designed and the factory is ready to start production

- Proper instruments are in place to guarantee that even full-scale production will satisfy customers' requirements

- Production and quality staff are in agreement with the customer's specifications

- All components and materials needed for production are in place

- Components and materials meet specified requirements

- Design of labels and packaging is properly

- If the opportunity arises, we will review also the first production

Production Control

Quality control is done early in the course of production. We ensure the earliest possible identification of problems with the product, production or personnel that may lead to quality problems with the final product.

DisposablesInc.com check:

- Production

- Production Processes

- Supplier Quality Process

- That the workers have the correct instructions

- The quality of components and materials used

Quality Control

Quality control is done later during the production stage. We make sure that no complications have occurred and that nothing has changed since the DPI first.

DisposablesInc.com check:

- Packing and packaging

- Product design and appearance

- The color, size, dimensions, weight, etc. conform to specifications

- Labels and logos

- Functional inspection

- Materials and Components

- Safety and Certifications

- Other requests from the client's direction

Pre-shipment Inspection

Quality control is done when the products are produced and ready they are to be packaged for export. We ensure that products meet customer requirements and to give the customer enough information to approve or reject the shipment of products. The products are inspected by sampling in accordance with the international AQL standard or according to customer requirements.

DisposablesInc.com check:

- Packing and packaging

- An overview of the product design and appearance

- Make sure the color, size, dimensions, weight, etc. conform to specifications

- Inspect the labels and logos

- Functional inspection

- Inspection of materials and components

- Verification of security and certifications

- Other requests from the client's direction

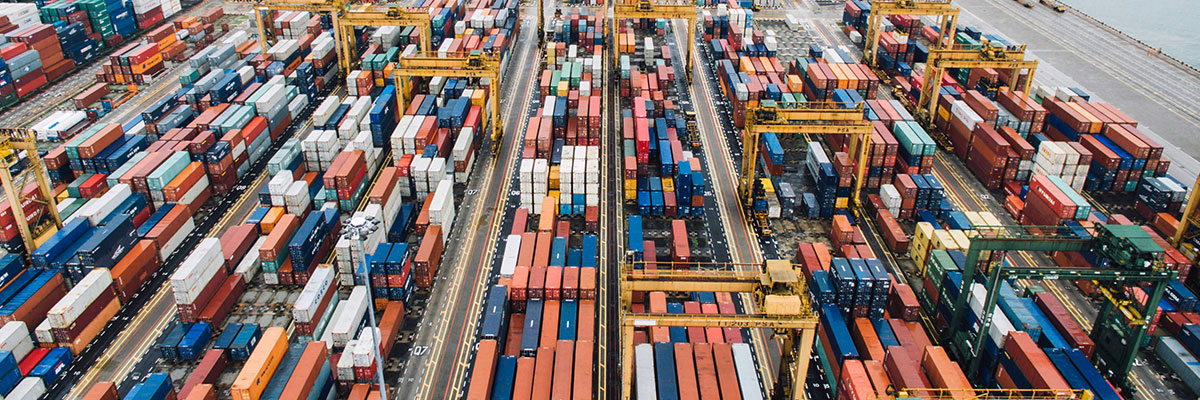

Control container loading

Quality control is done at the supplier's stock (or in our warehouse, the products from several factories). We are looking for a container permit, as well as quality and quantity of goods to be shipped.

DisposablesInc.com check:

- Packing and packaging

- Product design and appearance

- Quantity in accordance with orders

- The containers are in good condition

- The loading is correct